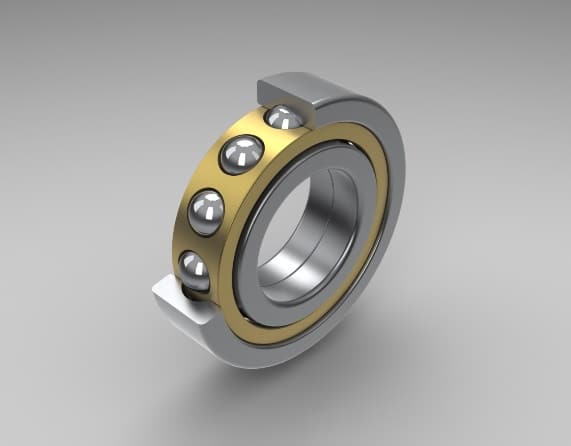

Angular contact ball bearings can take radial load and axial load simultaneously. Single row angular contact ball bearings can only take single direction axial load, so angular contact ball bearings are often used in pairs. The paired angular contact ball bearings with manufactured clearance are the most convenient. The contact angles between steel balls and the inner ring/outer ring fall into 15°, 25° and 40°. The larger the contact angle is, the higher axial load it can take. The smaller the contact angle is, the higher rotation speed. Generally, contact angle of 15° is applied to high precision and high speed bearings.

This type of bearing is designed with a certain contact angle, so they are suited to take single direction axial load or combined load. Structurally, axial thrust load will be generated after taking radial load, so angular contact ball bearings are often used in pairs, or more than two sets matched. The rigidity of single row angular contact ball bearings can be improved through preloading. Therefore, they are applied to the spindles of machine tools with high rotating precision.

The contact angles of standard products including 15°, 25°, 40°. The cages of bearings with 15° and 25° contact angles are often made of plastic. The materials of the cages of bearing with 40° contact angle are made of copper, nylon, steel sheet, etc.

In addition, the quantity of the steel balls may also vary with the structure of the cage even for the same type; accordingly the load ratings are also different from the values specified in the specification table.

For angular contact ball bearings with contact angles of 15° and 25°, products with high precision of class P4 of higher are available.

These products are especially suitable for the spindles of high speed and precision machine tools and spinning machines.

Angular contact ball bearings can be matched back to back, face to face, or as tandem matched pairs.

The inner and outer rings of the back-to-back matched bearings are combined into one structure, which can take two directional axial loads, and has large offset load capability. They can be used as fixed end bearings.

Pressed cages or nylon cages are normally used.

Four-point contact ball bearings are normally composed of an inner ring and two pieces of half outer rings or an outer ring and two pieces of half inner rings, which can take axial loads in both directions.

When contact angle is 35°, the large axial load capacity makes it suitable to take pure axial load, or combined load with large axial load.

Machined cages made of copper alloy are often used.

Magnetic clutch bearings for automobile compressors are dedicated products designed and manufactured according to the mounting dimensions and working conditions provided by customers. This kind of bearing is similar to a double row radial ball bearing in structure, but double row ball bearings for magnetic clutches have the following advantages:

Since double row ball bearings for magnetic clutches of air conditioners operate at high temperature for a long time near the engine, special heat treatment process and high performance grease are adopted by C&U to ensure high temperature performance

Due to the difficult working environment and long-term exposure to dust contamination and water vapor, the requirements of this working environment are fully met by the unique sealing structure. These products feature high precision and low noise, and can be mass produced in all sizes and specifications.